280T Tandem Series Knitting Machine

Products Description

Tandem And Combine Carriage Working Mode Flexibility

The 280T is equipped two carriages, each with a full direction selection system. Carriage can combine together working as two knitting system and 80-inch full bed knitting in combine mode. Furthermore, shaping capability, multi-piece function support more than 7 pieces knitted independently in one time, without wasting materials through drawn thread divide. Tandem operation in the 280T thereby allows the machine to support a variety of production methods, significantly increasing the flexibility and productivity of the machine.

Carriage tandem model can be used for knitting high quality collar & sleeve. Carriage separate knitting wide 35inch work as two single system machines. Two carriages work same time with same design.

Technical Parameters

| Model | TC280T / TC280TI |

| Gauge | 12G/14G/16G |

| Knitting width | 52/80 inch |

| Knitting system | Single system two carriage 1+1 tandem |

| Machine speed | maximum speed up to 1.4m/s,128 optional sections, value available from 1-120. |

| Display | 10.4-inch full touch LED display, support multiple language (Chinese, English, Spanish, Turkish, Russian, Korean) |

| Feeder alternation | 4pc yarn feeder rail, equipped with 8+8 yarn feeders |

| Needle bed racking | Driven by servo,,maximum L&R racking distance up to 2 inch |

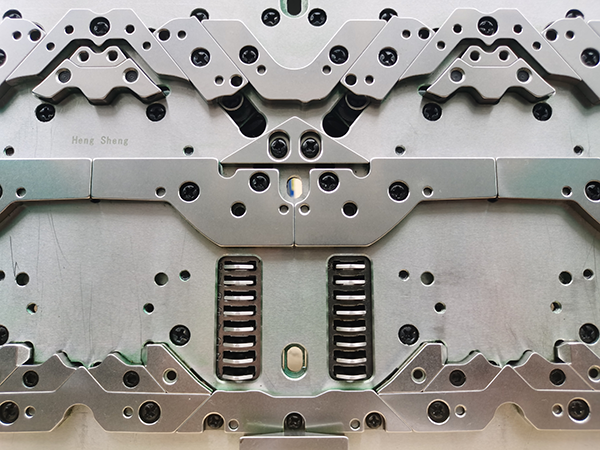

| Needle bed | Equipped with high precision needle bed and cam plate,support transfer function,inserted needle bed(optional) |

| Top tension device | 12pc standard new type single-blade ceramic wear-resistant and anti-static top tension devices (quantity optional) |

| Yarn feeding device | equipped with high rotation speed double anti-static ceramic roller, and anti-rewinding swing arm yarn feeding device |

| Drawing device | equipped with bigger roller and controlled by torque motor,128 optional sections, adjusting range 1-100 |

| Transmission device | servo motor, encoder record carriage position, yarn feeder parking position can be controlled automatically |

| Pattern design | program made by pattern design system, and could be transmitted by u disk or network. |

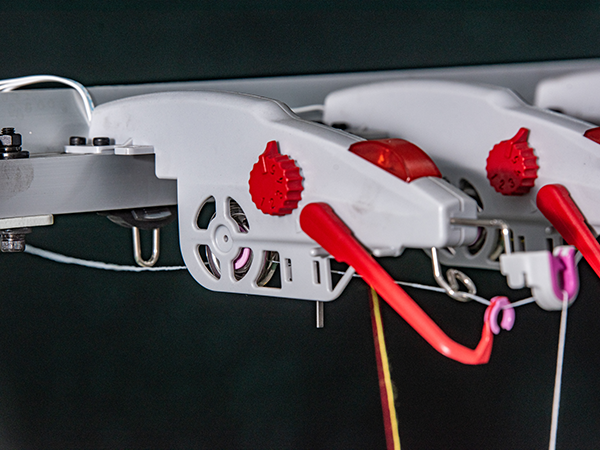

| Probe detection sensor | auto reset probe sensor, machine system support screening wrong feeder collision alarm |

| Loop density control | High-precision step motor,128 sections, adjustment range 1-180,support dynamic density in each single line |

| Date input | USB& RJ45port,512MB storage memory, support remote network transmission for program |

| Power consumption | Voltage:AC220V/380V frequency :50Hz/60Hz capacity:1KW |

| Safety equipment | All covers can reduce noise and dust protection,Infrared stop sensing , emergency stop,cut-off device |

Technical Features

High-precision Needle bed and special needle

Auxiliary roller Make drawing force more even and strong

Application Case