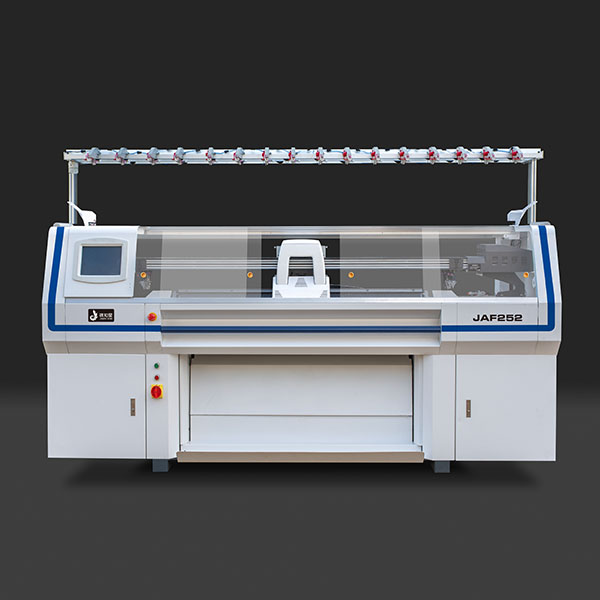

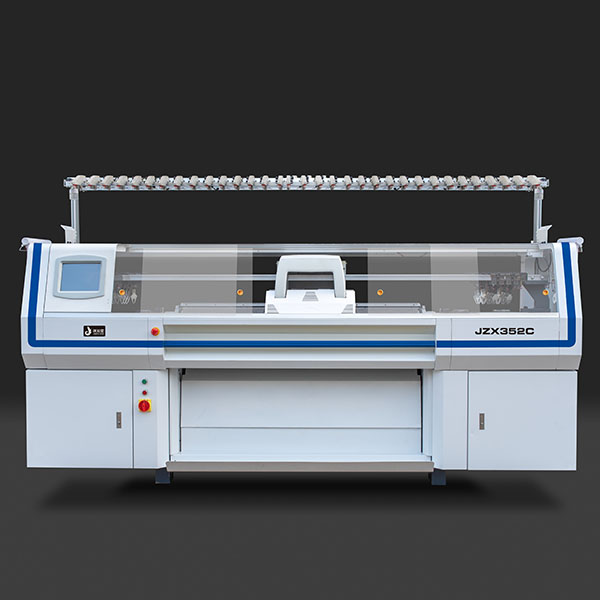

OEM Best Collar Making Machine Factories – Single Carriage Full Jacquard Collar Machine – Jinzhixing

OEM Best Collar Making Machine Factories – Single Carriage Full Jacquard Collar Machine – Jinzhixing Detail:

Technical Parameters

| Gauge | 12/14/16G |

| Knitting width | 52/80 inch |

| Knitting system | Single system two carriage 1+1 tandem |

| Machine speed | maximum speed up to 1.4m/s,128 optional sections, value available from 1-120. |

| Display | 10.4-inch full touch LED display, support multiple language (Chinese, English, Spanish, Turkish, Russian, Korean) |

| Feeder alternation | 3pc yarn feeder rail, equipped with 6+6 yarn feeders |

| Needle bed racking | Driven by servo,,maximum L&R racking distance up to 2 inch |

| Needle bed | Equipped with high precision needle bed and cam plate,support transfer function,inserted needle bed(optional) |

| Top tension device | 12pc standard new type single-blade ceramic wear-resistant and anti-static top tension devices (quantity optional) |

| Yarn feeding device | equipped with high rotation speed double anti-static ceramic roller, and anti-rewinding swing arm yarn feeding device |

| Drawing device | equipped with bigger roller and controlled by torque motor,128 optional sections, adjusting range 1-100 |

| Transmission device | servo motor, encoder record carriage position, yarn feeder parking position can be controlled automatically |

| Pattern design | program made by pattern design system, and could be transmitted by u disk or network. |

| Probe detection sensor | auto reset probe sensor, machine system support screening wrong feeder collision alarm |

| Loop density control | High-precision step motor,128 sections, adjustment range 1-180,support dynamic density in each single line |

| Date input | USB& RJ45port,512MB storage memory, support remote network transmission for program |

| Power consumption | Voltage:AC220V/380V frequency :50Hz/60Hz capacity:1KW |

| Safety equipment | All covers can reduce noise and dust protection,Infrared stop sensing , emergency stop,cut-o device |

Technical Features

High-precision Needle bed and special needle

Auxiliary roller Make drawing force more even and strong

Application Case

Product detail pictures:

Related Product Guide:

Good quality comes initial; company is foremost; small business is cooperation is our business philosophy which is frequently observed and pursued by our business for OEM Best Collar Making Machine Factories – Single Carriage Full Jacquard Collar Machine – Jinzhixing , The product will supply to all over the world, such as: St. Petersburg, French, Tanzania, Our business activities and processes are engineered to make sure our customers have access to widest range of products with the shortest supply time lines. This achievement is made possible by our highly skilled and experienced team. We look for people who want to grow with us around the globe and stand out from the crowd. We now have people who embrace tomorrow, have vision, love stretching their minds and going far beyond what they thought was achievable.

It is really lucky to meet such a good supplier, this is our most satisfied cooperation, I think we will work again!

Write your message here and send it to us